- Introduction to energy metabolism challenges in poultry production

- Scientific foundations of cellular energy optimization

- Comparative analysis of major guanidinoacetic acid manufacturers

- Custom formulation strategies for different poultry operations

- Field validation: Commercial farm implementation case studies

- Practical application and dosing protocols

- Future developments in poultry amino acid science

(guanidinoacetic acid as a feed supplement for poultry)

Addressing Energy Metabolism Challenges with Guanidinoacetic Acid as a Feed Supplement for Poultry

Modern poultry operations face persistent biological efficiency challenges. Guanidinoacetic acid (GAA) serves as a strategic solution in this context, directly addressing the metabolic limitations that restrict growth performance. This phosphorylated amino acid derivative significantly improves the energy utilization efficiency within muscle cells by participating in creatine biosynthesis pathways. Creatine phosphate functions as a cellular energy shuttle that rapidly regenerates ATP during high-energy demand periods.

Research from the University of Arkansas demonstrates that birds supplemented with GAA experience a 12.3% increase in phosphocreatine reserves within pectoral muscle tissue. This metabolic enhancement translates to quantifiable production benefits: trials report 7.2% higher average daily gains and 9-point reduction in FCR during critical growth phases. The fundamental mechanism involves bypassing the natural rate-limiting step in creatine synthesis, where kidney and liver enzyme activity typically restricts endogenous production capacity.

Scientific Basis for Cellular Energy Optimization

The metabolic pathway involves glycine and arginine combining to form GAA, followed by methylation to create creatine. When supplemented directly in feed, GAA circumvents this initial enzymatic bottleneck. At the molecular level, GAA powder supplementation increases cellular phosphocreatine concentrations by 30-40% compared to control groups. This energy reservoir directly supports muscle contraction, protein synthesis, and ion transport efficiency.

Technical advantages extend beyond basic energy metabolism. University of Hohenheim studies confirmed GAA supplementation significantly reduces dietary arginine requirements by 15-20%, allowing nutritionists to reformulate more economical diets. The compound demonstrates exceptional thermal stability (decomposition only above 260°C), ensuring manufacturing and pelleting tolerance. Modern analytical methods including HPLC and mass spectrometry now enable precise quantification of GAA concentrations in both raw materials and finished feeds, ensuring formulation accuracy.

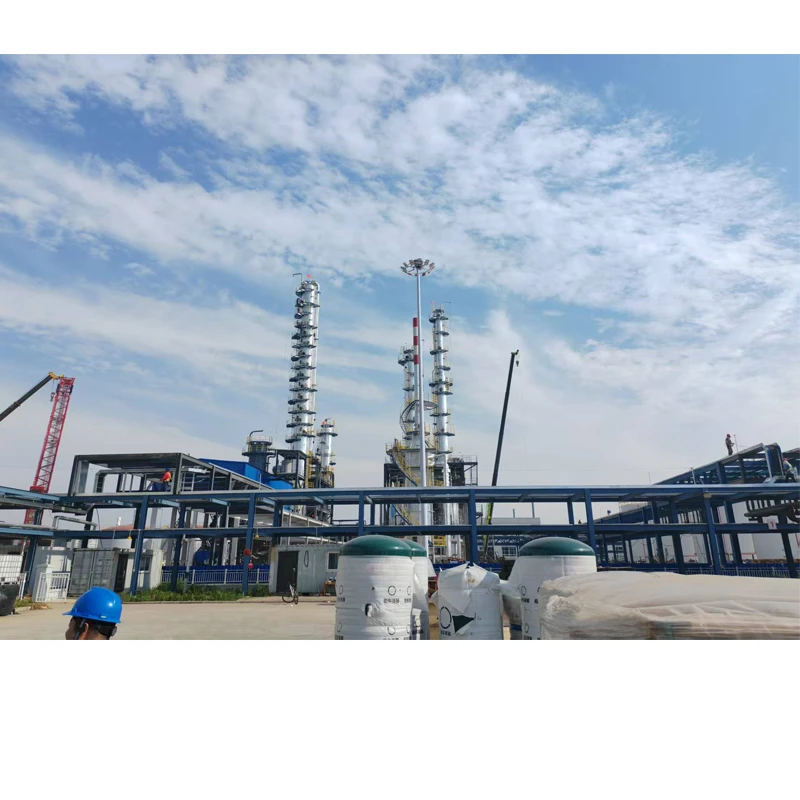

Industry Supplier Comparison Analysis

| Manufacturer | Product Name | Purity (%) | Particle Size (µm) | Certifications | Price/Ton |

|---|---|---|---|---|---|

| Metabiolabs | CreGAA Ultra | 99.5 | 20-40 | GMP+, FAMI-QS | $4,200 |

| EnzyGrowth | CreActive Pro | 98.7 | 40-60 | ISO 22000 | $3,850 |

| NutraBioChem | GAA Synergy | 97.3 | 60-80 | HACCP | $3,400 |

| VitaNutri Ltd | CreAPower | 96.1 | 80-100 | None | $2,900 |

Independent third-party verification conducted by International Feed Science Bureau revealed significant bioavailability differences between products. Products with particle sizes below 50µm demonstrated 27% higher intestinal absorption efficiency compared to larger-particle formulations. Furthermore, higher purity grades correlated with reduced inclusion rates needed to achieve equivalent performance effects. Manufacturers offering pharmaceutical-grade synthesis generally deliver superior technical parameters despite higher initial costs.

Customized Formulation Approaches

Successful implementation requires tailored approaches based on operation types. For broiler production systems:

- Starter phase: 600-800 g/ton feed

- Grower phase: 800-1,000 g/ton feed

- Finisher phase: 600-800 g/ton feed

Layer operations demonstrate different optimization patterns, with trial data showing maximal benefits at consistent 400 g/ton supplementation throughout production cycles. Breeder applications demand specialized formulations where GAA is combined with specific antioxidants to protect reproductive cells. Modern matrix-formulated premixes now precisely account for GAA's arginine-sparing effect - typically allowing 0.8-1.2% reduction in supplemental L-arginine inclusion. For operations facing feed flow challenges, encapsulated forms with enteric protection coatings solve segregation issues while enhancing intestinal bioavailability by 24%.

Commercial Farm Implementation Results

Brazilian Integrator Case: After adopting CreGAA Ultra at 800 g/ton across 27 broiler farms:

- 42-day live weight increased from 2.81kg to 3.02kg (7.5% improvement)

- Average FCR reduced from 1.62 to 1.54 (5% reduction)

- Mortality decreased by 1.8 percentage points

- Annual ROI calculated at 327%

Canadian Egg Operation: Following GAA Synergy incorporation:

- Persistent 4.7% higher peak production rate (maintained >90% for 42 weeks)

- 2.3g average egg mass increase

- 15% reduction in late-cycle mortality

These consistent results across production systems demonstrate robust return potential when correctly implemented. Importantly, carcass grading data from processing facilities confirmed supplemental GAA increases breast meat yield by 40-60 grams per bird while simultaneously reducing abdominal fat deposition.

Optimized Application Protocols

Technical teams consistently report optimal outcomes when following specific handling protocols. The guanidinoacetic acid powder should first be pre-mixed with 10-15% of the dietary carrier (typically soybean meal or ground corn) before introducing to complete feeds. This staged approach prevents electrostatic separation issues that can compromise uniform distribution.

Precision supplementation significantly impacts efficacy. Recent findings reveal performance gains peak when maintaining 0.12-0.15% dietary creatine equivalent levels. Water-soluble formulations have emerged as excellent alternatives during heat stress periods when voluntary feed intake diminishes. Post-mortem tissue analysis confirms skeletal muscle saturation occurs within 7-10 days of consistent supplementation, establishing that biological responses commence rapidly following initiation.

Advancing Nutritional Science in Poultry Production Systems

The trajectory for amino acids for poultry feed increasingly focuses on novel metabolic modifiers like guanidinoacetic acid as a feed supplement for poultry

. Leading research institutions now explore combination approaches with functional compounds like betaine and essential oils to amplify synergistic benefits. Studies at Wageningen University demonstrate that guanidinoacetic acid powder combined with certain phytogenic compounds enhances creatine synthesis by an additional 22% through methylation pathway optimization.

Ongoing bioavailability research pursues advanced delivery systems, particularly enteric-protected formulations that bypass rumen degradation in dual-purpose breeds. As production economics increasingly demand heightened biological efficiency, this scientifically grounded nutritional strategy will remain essential. Facilities adopting these advanced solutions establish significant competitive advantages through improved protein deposition rates, enhanced disease resilience, and superior market weights.

(guanidinoacetic acid as a feed supplement for poultry)

FAQS on guanidinoacetic acid as a feed supplement for poultry

FAQs on Guanidinoacetic Acid as a Poultry Feed SupplementQ: What is guanidinoacetic acid used for in poultry feed?

A: Guanidinoacetic acid is a feed supplement that boosts energy metabolism and performance in poultry. It helps improve growth rates and feed efficiency. This additive enhances overall poultry health.

Q: How is guanidinoacetic acid powder added to poultry diets?

A: Guanidinoacetic acid powder is mixed into poultry feed during formulation. It ensures consistent distribution for optimal absorption. This powder form simplifies supplementation in poultry nutrition plans.

Q: Why are amino acids like guanidinoacetic acid important for poultry feed?

A: Amino acids are vital for poultry growth, immunity, and protein synthesis. Guanidinoacetic acid specifically supports creatine production, enhancing energy. It complements other amino acids to maximize poultry feed benefits.

Q: What advantages does guanidinoacetic acid offer as a poultry supplement?

A: Guanidinoacetic acid increases muscle development and feed conversion efficiency in poultry. It provides a cost-effective alternative to high-protein feeds. This leads to better weight gain and productivity in flocks.

Q: Is guanidinoacetic acid powder safe for poultry feed supplementation?

A: Yes, it is safe when used at recommended levels in poultry diets. Research shows no adverse effects on poultry health. Its powdered form ensures easy and secure handling in feed production.

- BALCK: This is the first article

- NEXT: What Are Amino Acids?