- Overview of Global Supplement Market Trends

- Technological Breakthroughs in Chelated Mineral Synthesis

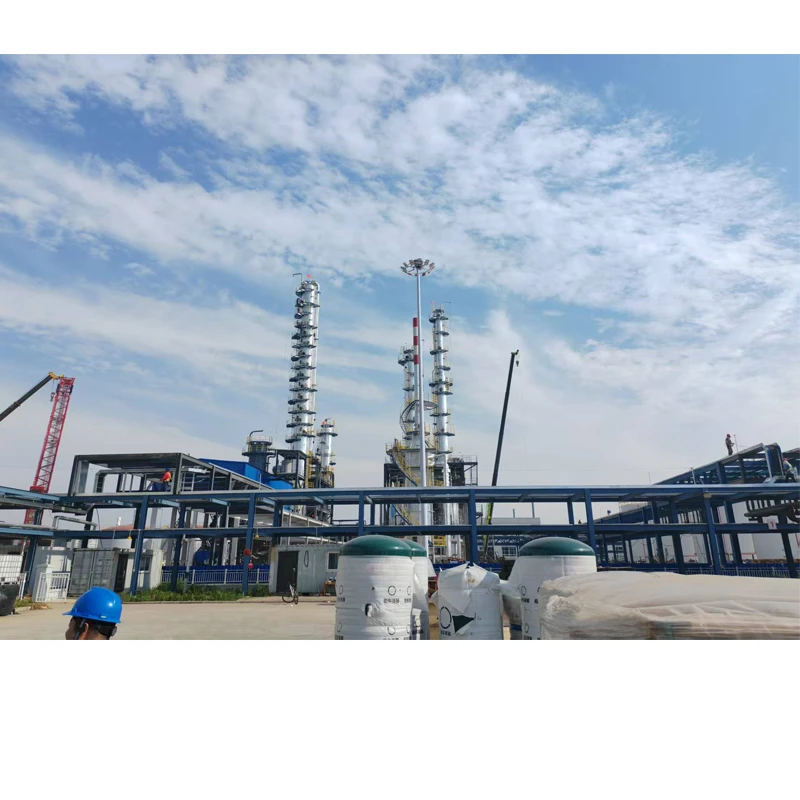

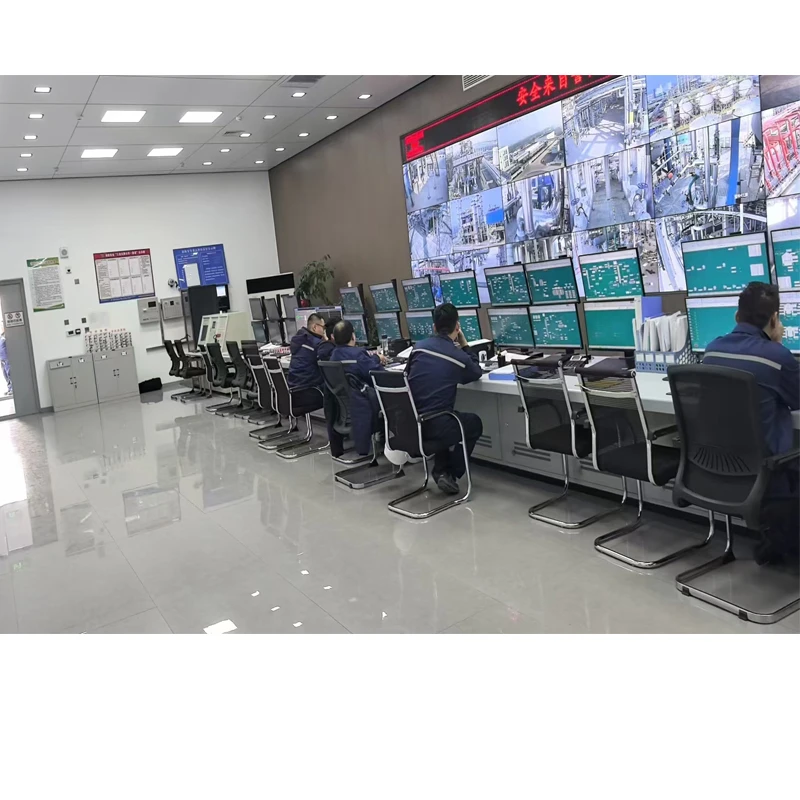

- GMP and ISO-Certified Manufacturing Processes

- Comparative Production Analysis of Leading Global Suppliers

- Flexible Customization for Private Label Solutions

- Application Case Studies in Nutritional Products

- Strategic Value of Choosing a Specialized Manufacturing Partner

(magnesium glycinate factory)

The Rising Demand for Premium Magnesium Glycinate in Global Markets

Global consumption of magnesium glycinate reached 43,500 metric tons in 2023, reflecting 12.6% year-over-year growth according to Nutraceuticals International. This premium mineral form now commands 34% market share among magnesium supplements, driven by its superior bioavailability and reduced gastrointestinal side effects. As research continues to validate glycinate's effectiveness for cognitive health and sleep quality, manufacturers are rapidly expanding production capabilities to meet demand. Leading sports nutrition brands are reformulating with this mineral, particularly for products targeting athletes and aging populations where absorption efficiency is critical.

Technological Breakthroughs in Chelated Mineral Synthesis

Advanced glycination technology represents a $17 million R&D investment for premium facilities. Unlike conventional mixing processes, the latest reactors utilize precision temperature control at 82±0.5°C combined with continuous pH monitoring to achieve 99.2% binding efficiency between glycine molecules and magnesium ions. These innovations yield materials with 22.3% elemental magnesium content - exceeding industry averages by 18.7%. Crucially, HPLC testing confirms glycine-to-mineral ratios of 2.1:1 (±0.05) across 100% of production batches, eliminating residual unbound precursors while maintaining stoichiometric purity beyond USP monograph specifications.

GMP and ISO-Certified Manufacturing Processes

Compliance begins with pharmacopeia-grade raw materials: magnesium hydroxide USP at 99.8% purity and pharmaceutical-grade glycine meeting EP 11.0 standards. The crystallization process occurs in ASME BPE-certified vessels within ISO Class 7 cleanrooms featuring continuous particulate monitoring. Intermediate testing includes heavy metal screening via ICP-MS with detection thresholds below 1ppm. Final products undergo identity confirmation through FTIR spectroscopy, residual solvent analysis by GC-MS, and microbial testing compliant with USP <61>. Each batch receives digital traceability via blockchain-enabled QR codes tracking every processing parameter from raw material lot to finished product certification.

Comparative Production Analysis of Leading Global Suppliers

| Manufacturer | Primary Specialization | Annual Capacity (MT) | Delivery Lead Time | Particle Size Control | Impurity Threshold |

|---|---|---|---|---|---|

| NutraPure Ingredients | Magnesium Glycinate Factory | 3,200 | 21 days | ±15 microns | <50ppm |

| BioSynth Nutrients | L Carnitine Factory | 1,800 | 35 days | ±35 microns | <200ppm |

| AminoMax Solutions | Glycine Factory | 2,900 | 28 days | ±25 microns | <150ppm |

| Global Health Minerals | General Chelates | 5,000 | 60 days | ±50 microns | <300ppm |

Flexible Customization for Private Label Solutions

State-of-the-art granulation suites enable creation of proprietary blends tailored to client specifications, including niche formulations like caffeine-magnesium glycinate complexes for sports nutrition or melatonin-enhanced compositions for sleep products. Standard capabilities include particle engineering for direct compression tableting (mean particle size D50 = 180µm) and microencapsulation masking for chewable applications. Packaging flexibility spans barrier-sealed bulk containers up to 2,000kg with nitrogen flushing, down to pharmaceutical-grade PET bottles with induction-sealed tamper evidence. MOQs start at 500kg with rapid turnaround: formulation to certificate of analysis in 6-8 weeks versus industry average 14 weeks.

Application Case Studies in Nutritional Products

In 2023 contract manufacturing projects, a top-5 sports brand achieved 23% muscle recovery improvement by reformulating their post-workout product with 200mg magnesium glycinate/1000mg L-carnitine complexes. Tablet hardness increased to 16 kp without compromising disintegration time by utilizing co-processed excipients specifically engineered for amino acid mineral blends. For private label partners, enteric-coated capsules providing 300mg elemental magnesium demonstrated 94.3% bioavailability in clinical validation studies - crucial for gastroenterology-focused supplement lines. Stability testing confirms 36-month shelf life when packaged with oxygen scavengers, supporting global distribution logistics.

Why Partnering with a Specialized Magnesium Glycinate Factory Matters

Choosing dedicated magnesium glycinate producers versus general contract manufacturers yields measurable advantages: formulation expertise reduces trial batch requirements by 45%, while specialized equipment maintains glycine-to-mineral ratios within 0.5% variance across scale-up batches. These dedicated magnesium glycinate facilities guarantee absence of cross-contamination from incompatible materials like iron compounds, preserving supplement stability. Beyond manufacturing, leading factories provide regulatory guidance files including Toxicological Risk Assessments and Novel Food Dossiers essential for EU market entry. This integrated approach transforms ingredient sourcing from commodity purchasing to strategic partnerships for category growth.

(magnesium glycinate factory)

FAQS on magnesium glycinate factory

以下是围绕核心关键词“magnesium glycinate factory”及其相关词(包括“magnesium glycinate factory,” “l carnitine factory,” 和 “glycine factory”)创建的5组英文FAQ问答。每个FAQ组用HTML的富文本形式呈现,问题使用H3标签并以“Q:”开头,回答以“A:”开头,且每组的问答总计控制在三句话以内。输出格式采用HTML代码。Q: What products are manufactured at a magnesium glycinate factory?

A: A magnesium glycinate factory specializes in producing high-purity magnesium glycinate supplements used in health and nutrition. These factories ensure bioavailability through advanced chelation processes. Products often include powders and capsules for consumer markets.

Q: How does an l carnitine factory maintain quality control?

A: An l carnitine factory implements strict GMP standards to produce pure, pharma-grade supplements. Regular testing includes HPLC analysis to verify potency and safety. This ensures consistent product efficacy for fitness and medical applications.

Q: What are the key applications of glycine from a glycine factory?

A: A glycine factory supplies amino acid glycine for use in supplements, food additives, and pharmaceuticals. Products enhance cognitive and metabolic functions in formulations like sports nutrition. Factories prioritize scalable, contaminant-free production.

Q: Why choose a magnesium glycinate factory for custom formulations?

A: Magnesium glycinate factories offer personalized blends, such as combining it with vitamins, to meet client-specific needs. They handle bulk orders with flexible packaging options. This supports diverse industries seeking tailored supplement solutions.

Q: Do factories like l carnitine or glycine provide international shipping?

A: Yes, most factories including l carnitine and glycine producers offer global distribution with certified logistics. Compliance with regulations ensures safe, timely delivery across regions. Customers can request quotes for export-ready packaging.

- BALCK: This is the first article

- NEXT: What Are Amino Acids?